An artificial sugar beet for the eyes of Artificial Intelligence

Plant phenotyping – the science of gathering precise information and measurements on plants – has seen massive improvements recently, and the combination of sensor technology and AI methods will continue to change the way crops are assessed and improved. A new article in GigaScience demonstrates where this is going: Jonas Bömer and colleagues at the Institute of Sugar Beet Research (Göttingen) used Laser Scanning and 3D printing to create a detailed 3D model of a sugar beet plant, for use within sensor-driven phenotyping pipelines.

If a low-maintenance, 3D-printed model of a sugar beet is exactly what’s missing in your garden: go ahead, download the files from the thingiverse platform and feed them into an off-the-shelf 3D printer. It will look great next to your 3D-printed scorpion from a previous GigaByte paper!

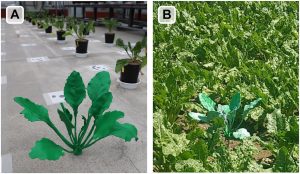

The 3D model in the greenhouse and in the field. Figure from Bömer et al. (c-by)

Of course, coming from a research article on plant phenotyping, the 3D sugar beet model was not made for its moderate decorative value. Rather, the model serves as a reference in phenotyping pipelines, both in the greenhouse and in the field. Modern plant breeding is a data-centric enterprise, involving machine learning algorithms and sophisticated imaging tech. In the past, phenotyping relied on measurements taken tediously by humans. Today, phenotyping pipelines are becoming more and more automated, using state-of-the-art sensor technology, often assisted by artificial intelligence. In addition to the efficiency gains of handing over the measurement work to automated pipelines, computer-assisted sensors can often capture complex information about a plant that would be very hard for humans to gather on a large scale.

The 3D model in a field setting. Image credit: Inst. of Sugar Beet research.

An artifical plant for the eyes of Artificial Intelligence

One crucial aspect in this new, sensor-driven world of crop breeding is the availability of precise reference material.The sensors need to be presented with data on a “standard plant” that is as close as possible to the real thing, including also more complex, 3-dimensional traits such as the angle at which the leaves are oriented. Having an actual artificial plant as a real-size reference is therefore preferable to just having data in the computer, or a flat, 2D representation. An actual model can also be included as a reference and internal control within a green house or test field among the real plants.

The new 3D-printed model of a sugar beet plant was generated with these applications in mind and has the additional advantage that the printing files are available for free download and reuse. This allows other scientists (and any sugar beet enthusiast, really) to recreate an exact copy of the reference sugar beet, making research done by different labs in different parts of the world more comparable. The affordability of 3D printing also means the approach can be adapted in resource poor settings, for example in developing countries.

From LiDAR scans to a printable 3D model

To gather the precise data for their realistic model, the authors used LiDAR (Light Detection and Ranging) technology. In short, a real sugar beet plant was scanned by a laser to create 3D data from 12 different viewing angles. After processing steps, this data was then fed into a commercial-grade 3D printer to create the actual real-size model of the sugar beet. The authors then tested the model for its intended use as point of reference, in the lab and in the field.

Author Jonas Bömer explains:

“In the field of three-dimensional plant phenotyping, the referencing of utilized sensor systems, computer algorithms and captured morphological parameters represents a challenging yet fundamentally important task. The application of additive manufacturing technologies for the generation of reproducible reference models presents a novel opportunity to develop standardized methodologies for objective and precise referencing, thereby benefiting both scientific research and practical plant breeding.”

The approach is not restricted to sugar beet of course, and the new GigaScience study demonstrates how the combination of artificial intelligence, 3D printing, and sensor technology can contribute to the plant breeding of the future – thus helping to feed the world’s population with healthy, delicious crops. GigaScience data scientist Chris Armit adds:

“The value in a printable 3D model is that you can print multiple copies, one per field of crops. As a low-cost phenotyping strategy, where the major cost is the LIDAR scanner, it would be fantastic to see this approach tested on other crops such as rice or African orphan crops, where there is a need for low-cost phenotyping solutions.”

References:

Bömer J; Esser F; Marks EA; Rosu RA; Behnke S; Klingbeil L; Kuhlmann H; Stachniss C; Mahlein AK; Paulus S. A 3D printed plant model for accurate and reliable 3D plant phenotyping. GigaScience 2024. https://doi.org/10.1093/gigascience/giae035

Data: Bömer J; Esser F; Marks EA; Rosu RA; Behnke S; Klingbeil L; Kuhlmann H; Stachniss C; Mahlein AK; Paulus S (2024): Supporting data for “A 3D printed plant model for accurate and reliable 3D plant phenotyping” GigaScience Database. https://doi.org/10.5524/102530

Anton Du Plessis, Johan Els, Stephan Le Roux, Muofhe Tshibalanganda, Toni Pretorius, Data for 3D printing enlarged museum specimens for the visually impaired, Gigabyte, 1, 2020 https://doi.org/10.46471/gigabyte.3

Sugar beet model from Bömer et al. at thingiverse:

https://www.thingiverse.com/thing:6626202

Browsable/embeddable 3D models in Sketchfab:

GigaScience’s collection of 3D-printable files (also including many museum specimen):

https://www.thingiverse.com/gigascience/designs

Also read the articles in our series “Plant Phenomics: Data Integration and Analyses“